Today marks an important moment in the development of this product, as today is the day I committed to manufacturing the batch. There is no going back now.

I’ve just finished paying a few key suppliers for some long lead time components. One of them is a camera. Here is its story.

This begins in 2015, when I first sent an email to an OnSemi salesperson, or maybe I filled out a form on its website, I can’t remember. I was reaching out to several possible suppliers at the time as I was first dipping my toes into this venture. Most of them never got back to me. As a tiny fish with no experience you aren’t worth anything to them, so when I never heard back I thought that was it. OnSemi had recently acquired Aptina, pretty much one of two camera sensors manufacturers in the world. The other is OmniVision and those guys dealt in even higher volumes (I will pretend Sony doesn’t exists as that’s a different planet entirely).

Then, one day, two months later, as I was checking my emails, bored in a basement classroom in DIT (such was my surprise I still remember the moment clearly), I got an email from OnSemi asking to sign an NDA for accessing the Image Sensor Portal, that is pretty much all of the datasheets, reference manuals, registers, etc. for the Aptina lineup. I thanked the person that emailed me many many many times pretending like I was cool and I could do without them, sent over the signed NDA (still uncertain as to whatever I would have heard from the guy ever again), and a few days later I had access to the documents.

I could now develop using Aptina sensors. Cool, right? Well… Let’s say expensive is a better term.

The Aptina chips I ended up using for the 1.3 GHz batch were the AR0132, a 720p HDR sensor and the AP0100, an Image Signal Processor, whose job is pretty much taking the video out of the camera and making it likeable to the human eye with subtle details like white balancing. Some hardware limitations I won’t get into didn’t allow me to do white balancing inside the chip receiving that video stream.

Those chips were around $30 and $13 each (source: octopart), so $43 going down the drain in camera chips alone. That doesn’t include connector, cable*, board, assembly, enclosure, lenses. Let’s leave it at expensive and let’s say that camera was $80 a piece in cost.

Now, if you are planning on spending more money and time in making a 2.4 GHz version of your product, you better have a plan to lower that cost. The plan included begging OmniVision, whose sensors are cheaper, and did result in a signed NDA with them as well (Yippee!), but this is not where this story is going. The HDR sensor here is still from OnSemi.

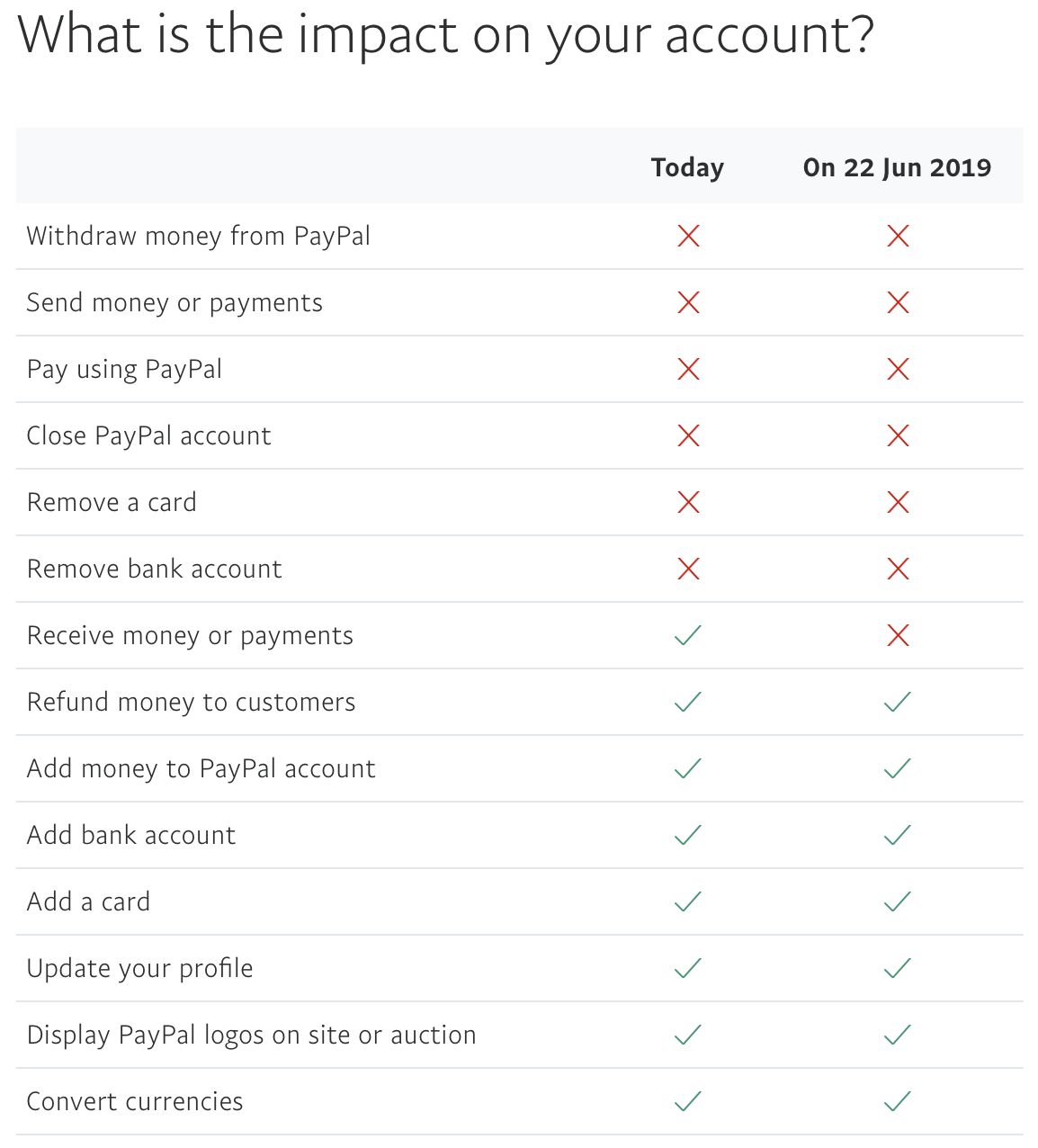

The winner today is called AS0140, which is a single chip solution with sensor and processor, all in one single chip. It’s mostly used as a rear view camera for high end vehicles, so you can thank people with expensive cars for this chip’s existence.

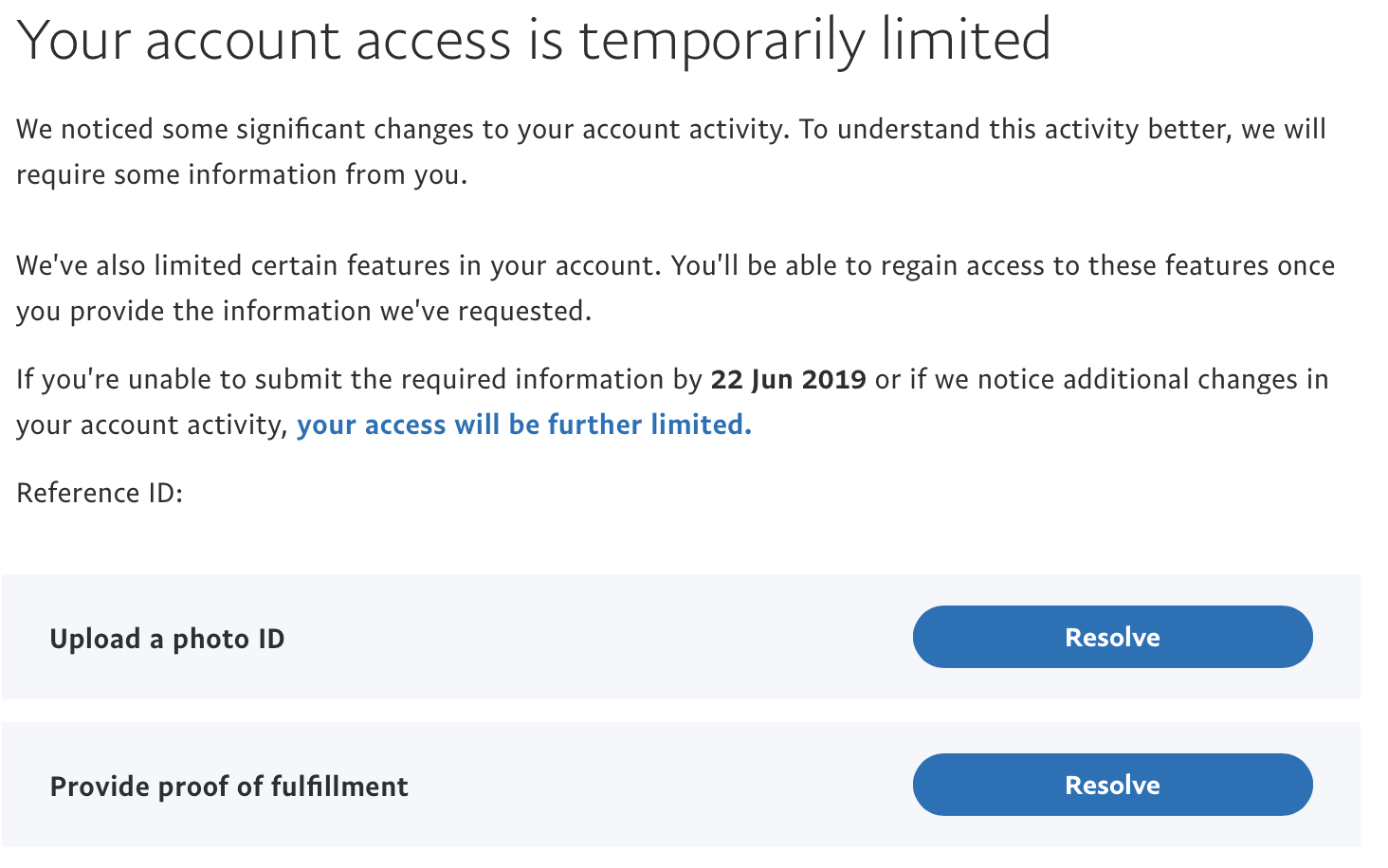

Now, as you can imagine, people making cars don’t make them 10 at the time so the minimum order quantity for this chip last year was 2970 units. Digikey lists them at $15 a piece, so that’s a cool $45k if you want to use that camera. Reaching out to my sales contact didn’t help and no one had it in stock in lower quantities.

3k units is way too high and I couldn’t afford spending 45k in expensive silicon, so that was it. Again. Or so I thought, because I did just place an order for it with a supplier that had it in stock and was ok with selling to a mere mortal, so there was a way, one way that didn’t include any of the simpler channels, that is not listed on octopart and didn’t pass through Asia. The answer was cold emailing people.

I guess not giving up pays off, some times. But only some times.

The rest of the story was as simple as purchasing a $300 development board to add on top of something else you paid $780 for, and you are all set.

Here is what that looks like:

*The KEL microcoaxial camera cable was something ridiculous like $10 a piece and 3 months in lead time, which they didn’t even met.